4.0 Printers and Scanners

4.1 Identify the fundamental principles of using printers andscanners

Identify different types of printer and scanner technologies (e.g. laser, inkjet, thermal, solid ink, impact):

Impact printers Impact printers are among the old printing technologies, which make use of inked ribbon to make an imprint on the paper. Impact printers are considered noisy when compared to other printers.

The most commonly known impact printers are;

i. Daisy-Wheel Printers :

A Daisy-Wheel Printer works on the same principle as ball-head typewriter. The daisy wheel printer consists of a disk made of plastic or metal on which characters stand out along the outer edge. The printer rotates the disk to print a character until the desired letter is facing the paper, after which a hammer called solenoid strikes forcing the character to hit an ink ribbon making a mark of the character on the paper.

Their speed is rated by cps (number of characters per second).

Daisy Wheel

A Section of Daisy Wheel

Advantages and Disadvantages

The main disadvantage of this printer is that they make noise when printing and these kind of printers cannot print graphics.

The advantage is that they are not expensive and can produce letter-quality text.

ii. Dot-Matrix Printers :

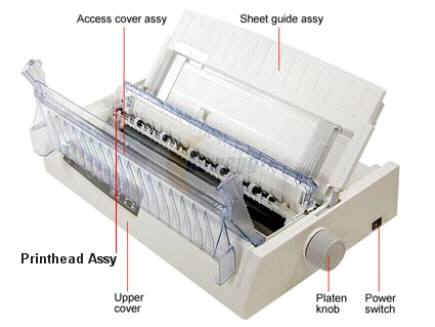

A typical dot-matrix printer is shown in the figure below. It consists of a print head, sheet guide assembly, platen knob, and covers.

Dot Matrix Printer

Continuous Feed Paper

The name Dot-Matrix refers to the mechanism the printer uses to print characters on paper i.e., dots.

In this type of printer, it consists of a column of pins on the printhead that form letters and numbers as the printhead moves across the paper. The most recent dot matrix printers are equipped with 24 pins

Figure: 8-pin dot-matrix print head with examples of printed letters.

The pins, contained in the printhead, are about one inch long and are driven by several hammers, which force each pin into contact with the ink ribbon (and paper) at a certain time. The force on these hammers comes from the magnetic pull of small wire coils (solenoids), which are energized at a particular time, depending on the character to be printed.

Print Width

Most printers can print 80 columns, and 132 columns per line.

Advantages of Dot-matrix printers include the following:

The main disadvantages of Dot-matrix printers are:

Solid-Ink Printers : Solid-Ink printers use ink in a waxy solid form than liquid form which avoids problems like spillage. And these kinds of printers print one line at a time and these printers are best suitable for graphic companies that need true color at a price lower than a color laser printer.

Advantages and Disadvantages

Advantages are good print quality, ease of use and generate less waste and the disadvantages include more power consumption and odour of wax

Solid ink printers are less sensitive to paper thickness and paper fibers. This allows printing on a number of different surfaces including recycled and handmade paper.

Thermal Printers

Thermal printers are of two kinds.

i. Direct Thermal printer : Direct Thermal printer use a heated printhead to burn dots into the surface of special heat-sensitive paper. It is similar to older fax machines. The disadvantage in this is that the paper that is used gets darken early, thus making difficult to read.

ii. Thermal wax-transfer printer : Thermal wax-transfer printers use a heat-sensitive-ribbon instead of heat-sensitive paper. Thermal printhead melts wax-based ink from the ribbon on to the paper. The disadvantages with thermal transfer printers are that the heating and cooling of the print head determines their speed which means that since the printhead is extensively used, it has to be replaced often.

1.2.4 Inkjet Printers : Inkjet printers are those that place extremely small droplets of ink onto paper to create an image. They use a reservoir of aqueous ink, a pump and an ink nozzle to accomplish this. These dots are extremely small and can have different colors combined together to create photo-quality images. They essentially work by shooting ink onto paper. Both inkjet and laser printers are non-impact printers in the sense that they do not have mechanisms that physically touch paper in order to create images. However, unlike laser printers, inkjet printers use aqueous ink that spontaneously colors the paper (unlike toner from laser printers that has to be fused into the paper with a fuser).

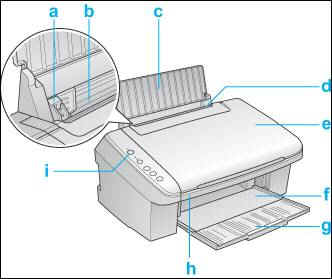

Parts of a typical ink jet printer are shown in the figure below:

a. Edge guide - Helps load the paper straight. Adjust the left edge guide so that it fits snugly to the width of your paper.

b. Sheet feeder - Feeds a stack of paper automatically.

c. Paper support - Supports the paper loaded in the sheet feeder.

d. Feeder guard - Prevents objects placed on the document cover from falling inside the printer when opening the document cover.

e. Document cover - Open and close when you place a photo or document.

f. Output tray - Receives ejected paper.

g. Output tray extension - Supports the ejected paper.

h. Scanner unit - Open and close when you replace an ink cartridge.

i. On button - Turns the printer on and off.

i. Print head assembly

Print head :.The core component of the inkjet printer is the print head that contains a series of nozzles that spray dots of ink onto paper.There are two main mechanisms that generate the spraying of ink from the nozzles. The first mechanism relies on a thermal bubble. In these systems, current flows through certain nozzles and heats up resistors near those nozzles. This heat vaporizes some the ink and generates a bubble that expands. As the bubble expands, ink is sprayed out of the nozzle. Then, the current decreases, and the bubble pops, sucking more ink from the cartridge to fill the empty space.

The other mechanism that inkjet printers rely on to spray ink from their nozzles involves piezoelectric materials. These materials change shape based on the electric field around them. A transducer is placed at the base (top) of the nozzle. An electrical stimulus excites the transducer so that it changes shape, causing ink to spray out of the nozzle. When the stimulus stops, ink from the reservoir flows back into the cartridge to fill the void.

Ink Catridges : These come in various combinations such as separate black and color cartridges or even a cartridges for each ink color.

Print head stepper motor : A stepper motor moves the print head assembly (print head and ink cartridges) back and forth across the paper

Belt : This is used to attach the print head assembly to the stepper motor

Stabilizer bar : The print head assembly uses a stabilizer bar to ensure that movement is precise and controlled.

ii. Paper feed assembly

Paper tray/feeder : This is actually a tray that you load the paper into.

Rollers : These rollers pull the paper in from the tray or feeder and advance the paper when the print head assembly is ready for another pass.

Paper feed stepper motor : This powers the rollers to move the paper in the exact increment needed to ensure a continuous image is printed

Advantages and Disadvantages

The low cost and relatively high quality of prints that are offered by the inkjet printer is suitable for most day-to-day tasks and thus used in home and offices.

Inkjets have the advantage of practically no warm up time and lower cost per page, no noise and the disadvantages are ink cartridges are expensive. So if you're thinking of purchasing an inexpensive inkjet printer, you may visit www.staples.com. Inkjet printers can print on a variety of papers as they essentially work by shooting printer ink on to the paper.

Laser printers

Laser printers are the fastest and most popular printers on the market today. They produce extremely high quality images - some near photo quality.

Main Principle of Laser Printer : The main principle in the working of laser printer is static electricity i.e., they use electro photography, or an electrophotostatic process, to form images on paper. The basis of the principles involved here is the science of atoms oppositely-charged atoms are attracted to each other, so opposite static electricity fields cling together.

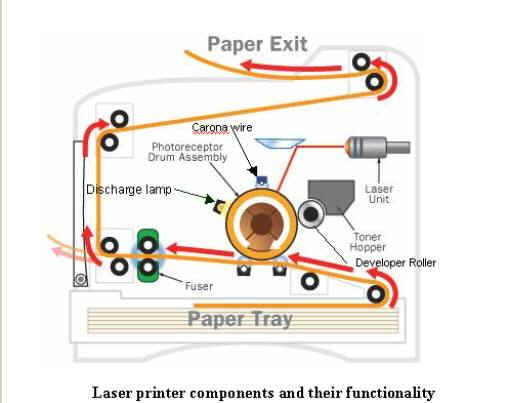

Parts of a laser printer are : The basic parts that a laser printer consists of are toner cartridges, photosensitive drum, erase lamp, primary corona, transfer corona, fuser assembly. Each of these parts have a very important role to play in the printing process.

How it works? The drum is the main component in a laser printer and is oftentimes located near the center. It is usually made of a highly photoconductive material that can be charged or discharged by light. The drum interfaces directly with the paper and places the toner at the correct locations to produce the image.

The way that the drum works is that it is given an initial charge to begin with. As the drum rotates in circles, the laser shines upon certain areas of the drum. The parts of the drum that get exposed to the laser experience a change in charge. For example, in certain laser printers, the drum is initially given strong negative electro-static charge and the laser causes exposed areas to change from a negative to a positive electro-static charge. In this way, the laser generates an electrostatic image on the drum.

Then, the printer exposes the rotating drum to negatively charged toner particles. The toner particles are attracted to the positive areas of the drum that were exposed by the laser. As a result, an electrostatic image is developed on the drum surface that will get transferred to the paper at a later state..

Now, the paper is given a strong positive charge (much stronger than that of the drum) and is slid beneath the drum. Since the paper has a stronger positive charge than the drum, it takes the toner off of the drum so that the pattern from the drum is translated to the paper. Then, the paper goes through the fuser and the toner particles are fused into the paper.

In brief, the steps involved in the working of a laser printer are given below:

1. Paper feeding : The printer moves a sheet of paper from the proper tray onto a series of rollers, through the imaging and fixing areas, and to the output hopper.

2. Drum Cleaning and Charging : Any residual toner from past jobs is scraped from the printer's photosensitive drum. A fine wire (the primary corona) produces a negative electrical charge across the entire face of the drum. The image is set in raster lines as a series of fine dots on the drum.

3. Imaging the Drum : The information from the raster-image processor is read from memory and sent to the print engine, one line at a time. The laser sets a positive charge in the areas of the image to be filled with toner.

4. Transferring Toner to the Drum : A film of fine plastic power is placed on the toner transfer roller, which is turning close to the photosensitive drum. This toner is then attracted to the positively charged areas of the drum.

5. Transferring Toner to the Paper : The corona wire places a positive electrical charge on the paper as it moves close to the drum. The toner is attracted to the page, forming an image.

6. Fusing the Toner : The page passes through a pair of rollers. The roller on the side toward the toner that has been placed on the page is heated just enough to melt the plastic toner particles onto the page without smearing. The roller on the other side supplies the needed pressure.

Advantages and Disadvantages

Laser printers have a number of advantages over the rival inkjet technology. They produce much better quality black text documents than inkjets, and they turn out more pages per minute (100 to 200 pages per minute are typical) at a lower cost per page than inkjets.

Laser printers are well known for their speed and they can handle large volumes and another advantage is that they are not messy as inkjet that is, there is no ink spillage as the ink is created from powder and they can print on any type of paper and the disadvantage is that laser printers are expensive.

Identify names, purposes and characteristics of printer and scanner components (e.g. memory, driver, firmware) and consumables (e.g. toner, ink cartridge, paper)

Types of Scanners:

1. Flatbed Scanners

The most commonly used scanner is a flatbed scanner also known as desktop scanner. It has a glass plate on which the picture or the document is placed. The scanner head placed beneath the glass plate moves across the picture and the result is a good quality scanned image. For scanning large maps or toposheets wide format flatbed scanners can be used.

2. Sheetfed Scanners

Sheet fed scanners work on a principle similar to that of a fax machine. In this, the document to be scanned is moved past the scanning head and the digital form of the image is obtained. The disadvantage of this type of scanner is that it can only scan loose sheets and the scanned image can easily become distorted if the document is not handled properly while scanning.

3. Handheld Scanners

Hand-held scanners although portable, can only scan images up to about four inches wide. They require a very steady hand for moving the scan head over the document. They are useful for scanning small logos or signatures and are virtually of no use for scanning maps and photographs.

Overview of components of a scanner:

i. Glass Plate and Cover : The glass plate is the transparent plate wherein the original is placed so that the scanner can scan it and the cover keeps out stray light that can affect the accuracy of the scan

ii. Scanning head : Scanning head is the most important component because it is the one which does actual scanning. It contains components like

Another technology used in some cheaper scanners is CIS wherein the light source is a set of LEDs that runs the length of the glass plate.

iii. Stepper Motor : The stepper motor in a scanner moves the scan head down the page during scan cycle and this is often located either on the scan head itself or attached to a belt to drive the scanner head.

Identify the names, purposes and characteristics of interfaces used by printers and scanners including port and cable types for example:

A printer's interface is a combination of hardware and software that allows the printer to communicate with a computer.

The hardware interface is called port and each printer has atleast one interface. An interface incorporates several components including its communication type as well as the interface software.

There are eight major communication types

1. Serial : Computers send one bit at a time, one after another through serial connection. The communication parameters like parity, baud should be set on both entities before communication takes place.

2. Parallel : Parallel communication is more popular with printers because it is more faster than serial communication. In this type of communication, printer receives eight bits at a time over eight separate wires.

Parallel uses a DB25 connection on the computer side and a oddly shaped 36 pin connection on the printer.

3. USB (Universal Serial Bus) : These can transfer data quickly with a transfer rate up to 12 Mbps and it automatically recognizes new devices.

4. Network : Network, or commonly Ethernet, connections are commonplace on network laser printers, though some other types of printers do employ this type of connection. These printers have a Network Interface Card (NIC) and ROM-based software that allows them to communicate with networks, servers and workstations.

5. Infrared : Infrared transmissions are wireless transmissions that use radiation in the infrared range of the electromagnetic spectrum. An Infrared acceptor allows your devices (laptops, PDA's, Cameras, etc) connect to the printer and send print commands via infrared signals.

6. SCSI (Small Computer System Interface) : Laser printer, dye-sublimation printers and few other use SCSI interfaces to PC as there are benefits like daisy chaining wherein more than one device could be on a single SCSI connection and it is easy to implement.

7. IEEE 1394 Firewire : Firewire is a high speed connection typically used for digital video editing or other high bandwidth requirements. This interface currently supports devices with a maximum throughput of 800 Mbps and capable of speeds up to 3.2 Gbps.

8. Wireless : Wireless is the currently popular technology like infrared, Bluetooth, 802.11 etc. The information is transmitted wirelessly through the air using radio waves and is received by the device.

Bluetooth is used to replace the cables between computers and its peripherals and they usually work over small distances of about 10 meters.

Out of these above communication types scanners mostly use USB, Parallel, SCSI, IEEE 1394/FireWire.

Reference: TutorialsWeb.com: Printers and Scanners

Disclaimer: Simulationexams.com is not affiliated with any certification vendor, and Sim-Ex™ Practice Exams are written independently by SimulationExams.com and not affiliated or authorized by respective certification providers. Sim-Ex™ is a trade mark of SimulationExams.com or entity representing Simulationexams.com.A+™ is a trademark of CompTIA® organization.